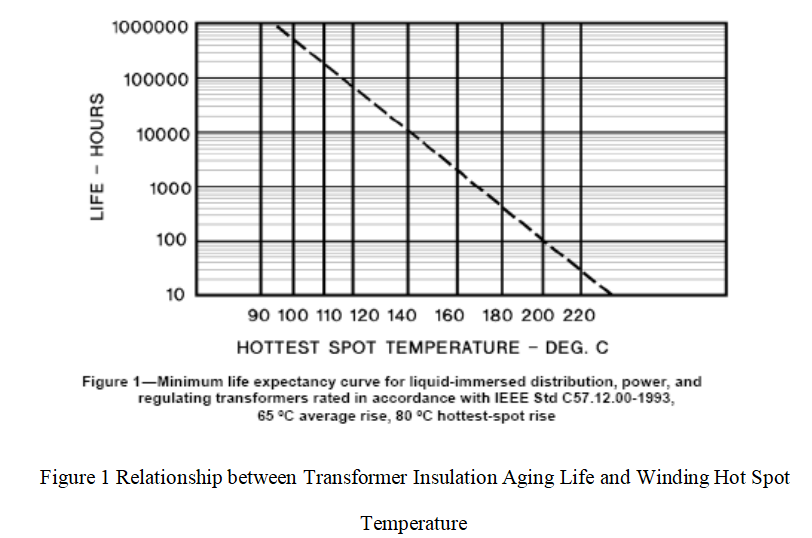

Solution of Optical Fiber Temperature Measurement for Transformer WindingSolution of Optical Fiber Temperature Measurement for Transformer Winding1. Necessity of Temperature Measurement for Large Transformers Power transformer is one of the most important electrical equipment in power system. Its operation status has a great relationship with the safe and reliable operation of power system. According to relevant statistics, the average accident rate of 110 kV and above transformers during 1990-1999 is about 0.69%. Due to the over-temperature operation of windings, insulation aging is caused, and the breakdown and burnout accidents of transformer windings account for a considerable proportion. For oil-immersed transformer, its life is mainly the life of solid insulation (fiber paper). Temperature, moisture and oxygen are the main factors contributing to insulation aging. Thermal effect is the most prominent factor when transformer is loaded. It can be said that thermal effect is the decisive factor of transformer aging. That is to say, the thermal aging speed of transformer winding insulation is related to the hot spot temperature of winding. As shown in Fig. 1, the insulation aging life of transformer decreases exponentially with the increase of hot spot temperature of transformer winding.

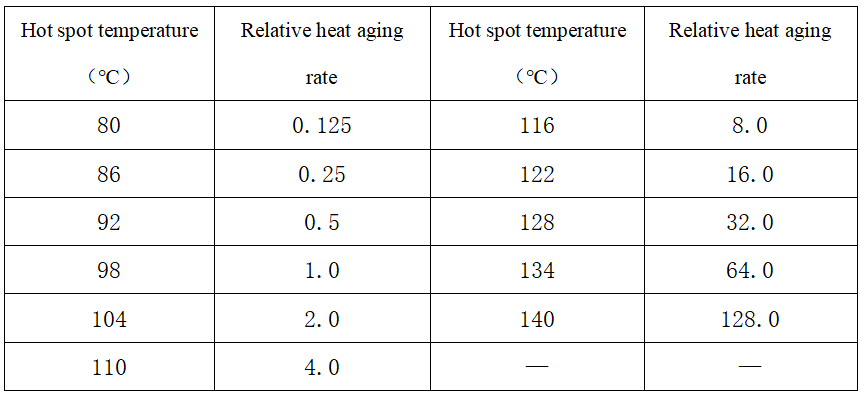

Oil-immersed power transformer designed according to GB1094 power transformer standard, GB/T15164-94 "Load Guidelines for Oil-immersed Power Transformer" stipulates that its hot spot temperature reference value is 98℃. That is, the relative aging rate of insulation at this temperature is 1.Within the range of 80-140℃, the aging rate doubles with the increase of 6K (so-called 6K rule). The relationship between the relative thermal aging rate and temperature of oil-immersed transformer is listed in Table 1. It can be clearly seen from Table 1 that the aging amount of transformer is equivalent to 128 hours of operation at 98℃ when it operates at 140℃ for 1 hour. It is very important to reduce the operating temperature of winding properly and control the hottest temperature of winding not exceeding the allowable temperature for prolonging the service life of winding insulators. Table 1 Relationship between Relative Aging Rate and Hot Spot Temperature of Oil-Immersed Transformer

For large oil-immersed power transformers with strong oil circulation, the time constant of oil is about 1-2 hours, while the time constant of winding is very small, only about 5-10 minutes. The difference between them is great. Therefore, due to the influence of heat conduction process, the current method of detecting oil top layer temperature to infer winding temperature as a criterion of transformer operation conditions is inaccurate, not timely and not intuitive. Therefore, it is necessary to adopt a new method to monitor the winding temperature of power transformer in operation and reflect the working temperature of winding in time.

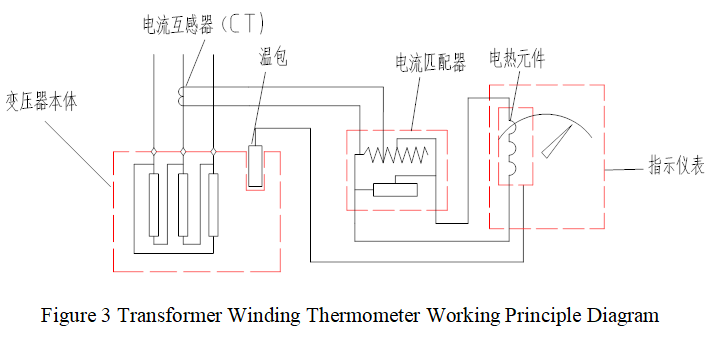

2. Working Principle of Conventional Winding Temperature Measurement Transformer winding itself is a charged body. It is difficult to measure winding temperature directly. Especially winding with higher voltage level can be realized by optical fiber technology, but the cost is high. So the common winding thermometer is actually a simulated value which can reflect the winding temperature by combining the oil temperature at the top of the transformer with the working current, not the actual temperature of the winding.

See Fig. 1, it is mainly equipped with a current matcher and an electrothermal element on the basis of an oil thermometer. The sensor of the thermometer - the temperature packet is inserted in the oil hole on the top of the transformer tank. When the transformer load is zero, the reading of the winding thermometer is the temperature of the oil surface on the top of the transformer tank. When the transformer is loaded, the current taken out by the transformer current transformer is proportional to the load. After being adjusted by the current matcher, it flows through the electrothermal elements embedded in the bellows, which generates heat, further expands the gas in the bellows and increases the displacement of the elastic elements of the meter. Therefore, after the transformer is loaded, the displacement of the elastic element is determined by the oil temperature of the top layer of the transformer and the load current of the transformer. The temperature indicated by the transformer winding thermometer is the sum of the oil temperature of the top layer of the transformer and the temperature rise of the coil to the oil. In the whole measuring device, the electrothermal element is the core component, because whether its heating characteristics can "truly" reflect the heating characteristics of transformer windings will directly affect the measurement results. Therefore, it is necessary to measure the temperature rise of transformer winding during temperature rise test, so that the current flowing through the heating element can be adjusted by current matcher, then the heating characteristics of the heating element are closer to the temperature rise characteristics of the transformer winding to the oil. It makes the value of thermometer more accurately reflect the temperature of transformer winding.

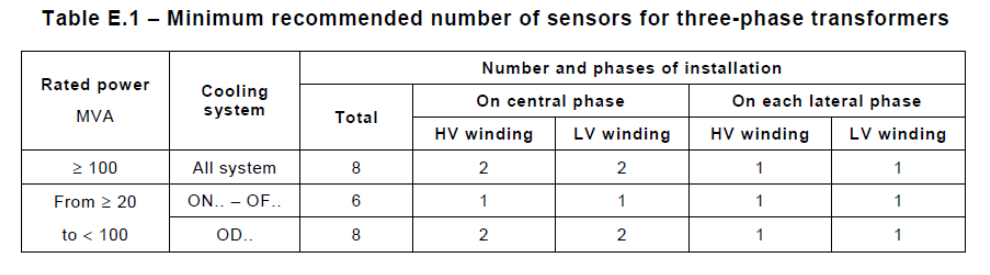

3. The Principle of Optical Fiber Winding Temperature Measurement There are three methods to determine the hot spot temperature of windings: direct measurement method, thermal simulation measurement method and indirect calculation method. Direct measurement method is to bury sensors in windings, which can accurately measure the hot spot temperature of windings on-line and in real time under high voltage and high magnetic field conditions by optical fiber transmission signals. It is the preferred method for hot spot measurement of transformer temperature rise test in the future. Taking our company’s fluorescent optical fiber temperature sensor as an example, the transformer winding hot spot optical fiber temperature controller is determined by measuring the individual intrinsic parameters (attenuation time) of the fluorescent body, and will not change because of the physical changes of the optical fiber, so the system is a system without calibration. The fluorescent material sensor is directly attached to the end of the optical fiber probe. The probe is made of material which has been proved to be compatible with oil-immersed high voltage power transformer for a long time and has excellent electrical performance. Since the 1980s, this technology has been applied to power transformers (for many years, it has been widely accepted as an industrial standard by large transformer manufacturers all over the world). During the temperature rise test, only the optical fiber probe (using the existing tools in the factory) is installed. The actual temperature of the winding hottest spot can be known by the data measured by the optical fiber probe, and the operation is simple. The system has 4 to 8 measurement channels with independent output and display. The temperature sensor is made of a stable high temperature resistant fluorescent material, which is directly placed at one end of the optical fiber. The principle is that when the light pulse emitted by the LED light source is sent to the temperature sensor contacting the winding through the optical fiber, the pulse excites the fluorescent material of the sensor to produce longer wavelength fluorescence. The temperature of the sensor is measured according to the decay time of the return fluorescence, then the temperature value and related system parameters are displayed by processing, and the temperature information is transmitted to the control room at the same time. The system can provide accurate winding temperature when the transformer is in peak load and emergency over nameplate capacity, and can make the transformer adjust the load in time according to the actual winding temperature measured. Power transformer temperature monitoring: Ø Winding temperature Ø Core temperature Ø Oil surface temperature 4. Advantages of Fluorescent Optical Fiber Temperature Control Technology Products for Transformers in Our Company Our company transformer fluorescent optical fiber temperature control technology product characteristics and applications: n On-line direct and accurate monitoring of transformer winding, core and oil surface temperature n Real-time reflection of temperature changes of monitored objects, timely and effective load control n Record the temperature change of the monitored object for a long time, establish the temperature file, and realize the prior management. n Easy installation, not affected by electromagnetic interference (1) Protecting Transformers and Prolonging Their Service Life through Real-Time Cooling Control When the transformer load exceeds the rating of the nameplate, whether it is continuous or short-term operation, the increase in coil temperature will age the insulation, thus reducing the life of the transformer. The coil temperature can be measured in real time with Herch’s fluorescent optical fiber temperature measuring product. The transformer coil temperature can be kept below the safety value by connecting the temperature controller simulation or RS-232 output to the transformer cooling equipment. Many transformers are subjected to short-term loads that last only a few hours. Even if the time is very short, insulation aging will occur and transformer life will be reduced, and accumulate each loss. The biggest disadvantage of traditional coil temperature indicator is its several hours lag besides its low accuracy. This is because the reading must be based on the measurement of the top oil temperature. As a result, transient overload may occur and the coil temperature indicator never feels it. When connected to the cooling equipment, the rapid reaction time of the thermostat can start the cooling system immediately. If the load is very heavy, the transformer cooling system is unable to keep the coil temperature below the safe value. Other relays of the thermostat can detect the high temperature, which makes the control system alarm and even make the transformer trip. (2) Increasing the Load of Transformers to Achieve Maximum Safety Due to the coil temperature measurement based on the top oil temperature measurement is relatively inaccurate, the transformer load must be conservative to ensure that the coil temperature is lower than the safety value. Some power companies can increase their load by about 10% by knowing the exact coil temperature when they use Herch’s fluorescent optical fiber temperature measurement systems. Herch’s fluorescent optical fiber thermometer product temperature controller provides analog output and a series of Digital interfaces (RS-232) to connect SCADA system or other data systems. 5. Domestic Application of Transformer Optical Fiber Winding Temperature Measurement In foreign countries, the temperature measurement of transformer windings has a history of more than 30 years. As early as the 1980s, fluorescent optical fiber temperature sensor probe is long compatible with oil-immersed high-voltage power transformer, and the improved technology has been applied to power transformer. The IEC standard of 2011 requires that transformers above 220 kV be forced to install optical fiber temperature measurement, and specifies the number of temperature measurement points.

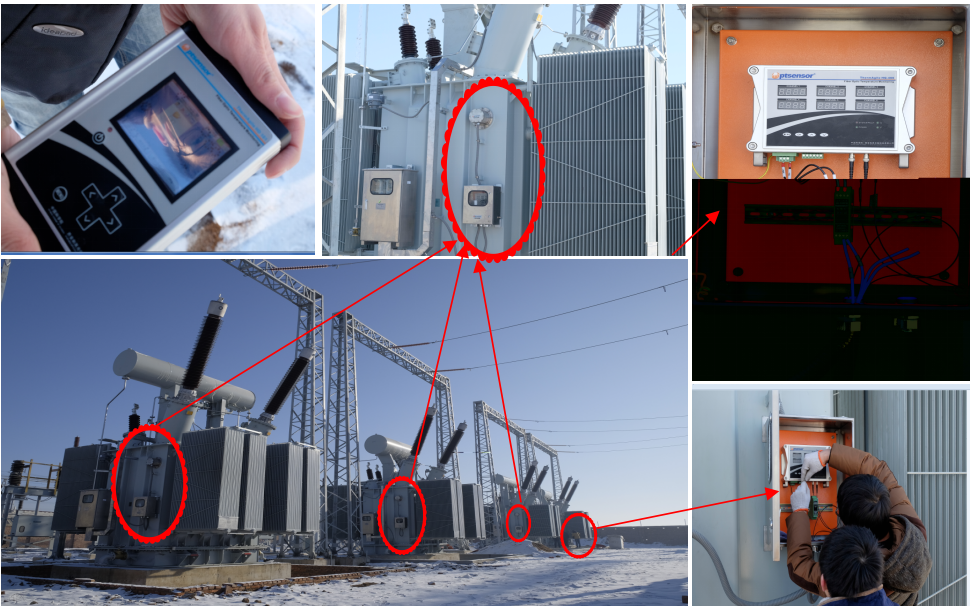

At home, large transformers exported abroad require winding optical fiber temperature measurement. Some domestic intelligent substations construct transformer windings using optical fiber temperature measurement. GB/T 1094.7-2008 "Power Transformer Part 7: Load Guidelines for Oil-immersed Power Transformers", 8.1.3 clearly stipulates that the use of optical fiber sensors to directly measure hot spot temperature rise increases the acquisition of correct thermal model of power transformers probably. 6. Herch’s Products Typical Case (1) Application in Traction transformer of Shenyang to Dandong High-speed Railway Traction Substation 220kV

(2)Application in oil-immersed transformer of XB 500KV

(3) Application in oil-immersed transformer of SanBianScience&Technology 110KV

Other cooperation units: Yunnan Transformer Factory, China Railway Industry, ABB, Tianwei Baobian, Xinjiang Special Transformer, Wujiang Transformer, Zhengtai Transformer, Changzhou Xidian, Changzhou Toshiba, Jiangsu Huapeng, Hengbian, Yinchuan Wolong, etc. 7. Composition of Product System

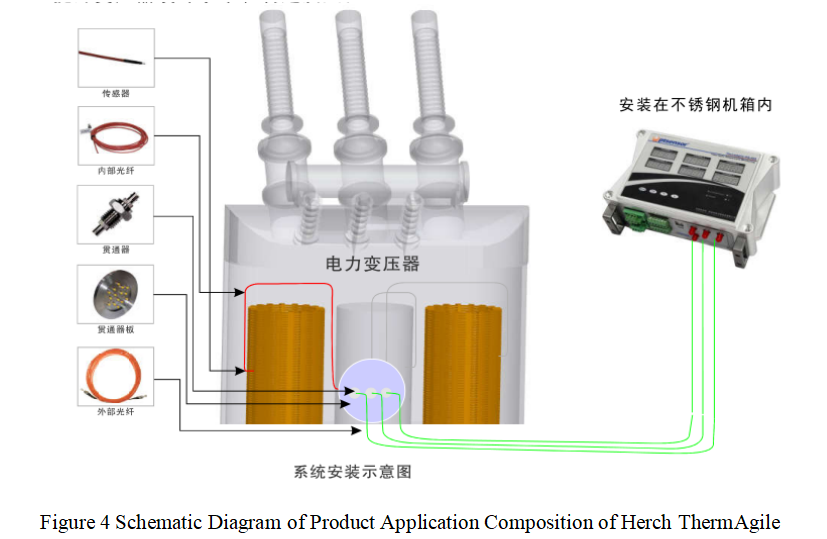

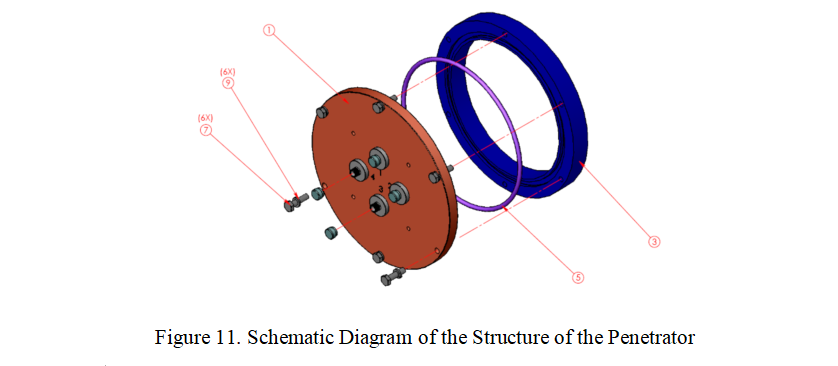

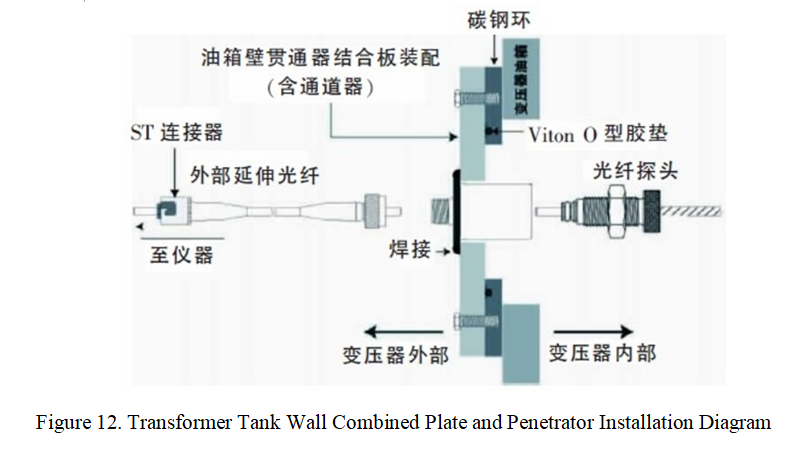

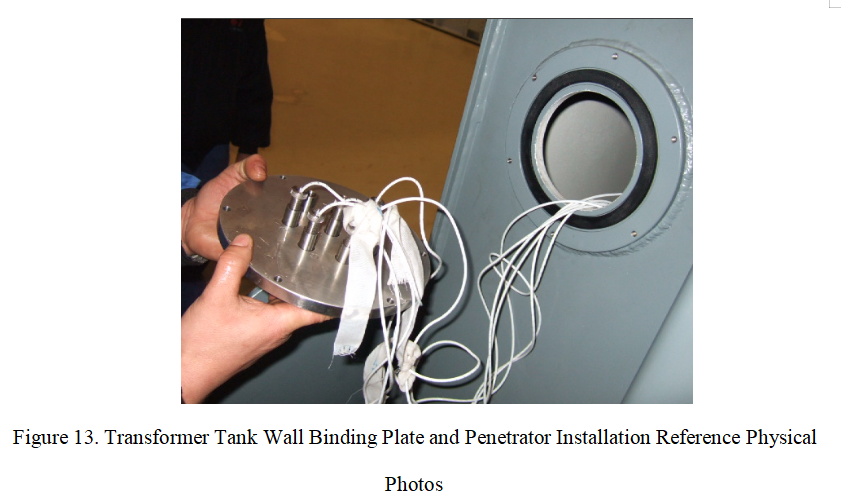

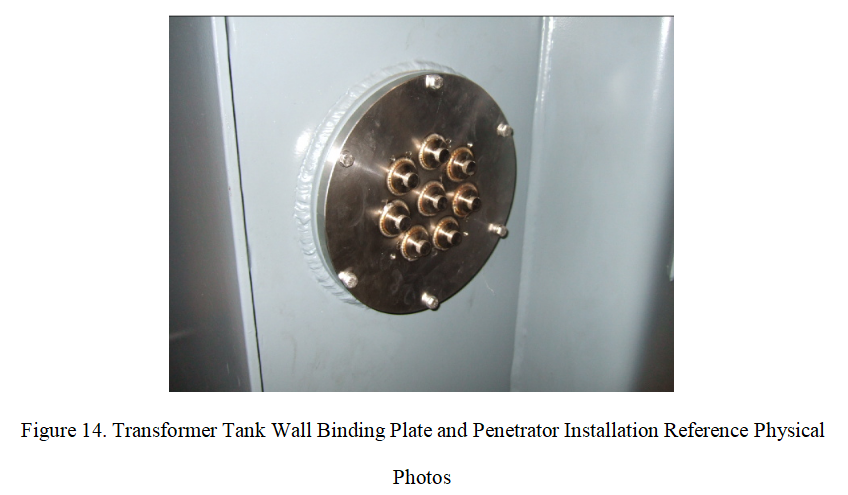

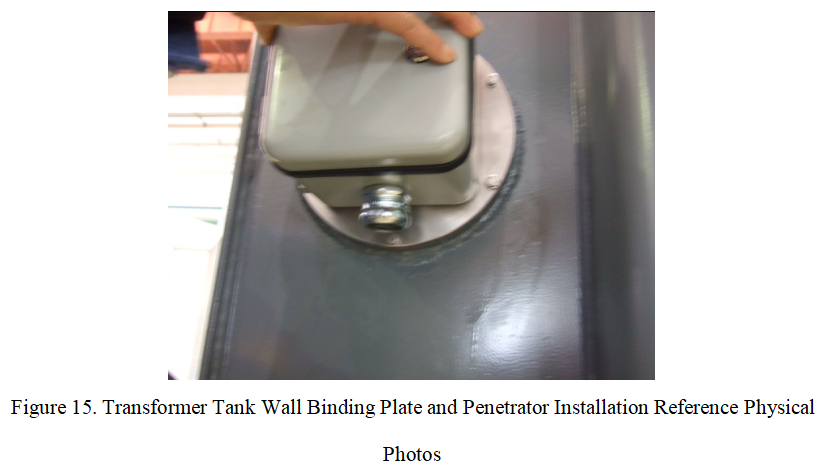

A complete set of ThermAgile equipment for oil-immersed transformers should include: 1. ThermAgile Temperature Controller Instrument (6-16 Channels) 2. Fluorescent optical fiber probe 3. Fuel tank wall penetrator 4. Fuel tank wall joint plate 5. Multi-in-one External Extended Optical Fiber 6. Optional tank wall shield (1) Reliability Ø Number of channels: 6-16 Ø Life equals life of transformer Ø Solid-state liquid crystal display light source life equals transformer life Ø No need to correct (2) Power Supply Ø General purpose DC or AC power supply: Ø Input power: 24 VDC or 220 VAC Ø Watts: 108W (maximum) (3) Temperature Ø Operating ambient temperature: - 30 to + 70℃ Ø Storage temperature: - 30 to + 75℃ Ø 80% relative humidity, no solidification (4) Performance Ø Measuring range: - 30 to 250℃ Ø Accuracy: +1℃ (5) Communication Ø Analog output: 4-20 mA (6) Digital Communication Ø Modbus, IEC 61850 Ø RS232, RS485, USB (7) Fiber Length Ø 1-20m (8) Probe Diameter Ø φ2.3mm (9) Service Life Herch’s fluorescent optical fiber probe is used perennially during the life of the transformer in the oil of the thermal transformer. ThermAgile electronic components can withstand temperature, humidity, electromagnetic induction shock and noise shock in this environment. The service life of LED measuring light source can reach that of ThermAgile thermostat. (10) Probe Design Herch’s development of its own intellectual property rights using simple temperature sensors, fuel tank wall penetrator, fuel tank wall bonding plate, external extension of optical fiber and protective shield. Strengthened optical fiber probe and extended optical fiber avoid the breakage of optical fiber, thus reducing the installation cost. The length of ThermAgile probe is made up of several different standard lengths. It can also be specially designed to suit different transformer designs and sizes. Optical fiber probe can be directly tied to the wire or placed in a pad between two wires. The probe is drawn from that point of the sensor to the side of the fuel tank wall penetrator. The design of oil seal penetrator can be customized according to the specific needs of customers. Equipped with international standard pipe threader, it can be installed from outside the tank through a suitable threaded hole. A carbon steel mounting plate with 4 or 8 pre-drilled threaded holes can accept 4 or 8 fuel tank penetrators and can be welded or screwed to the wall of the tank. External extended optical fibers are connected to the other side of the box wall penetrator and connected to the ThermAgile temperature controller. Special lengths of fibers can be provided as required. The hardware design is also suitable for simple and cost-effective sensor installation. The self-test function of ThermAgile electronic device can check probe and optical fiber during installation.

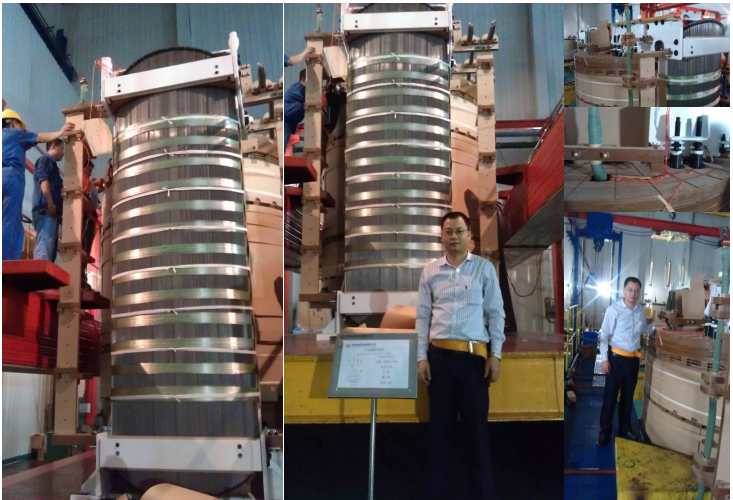

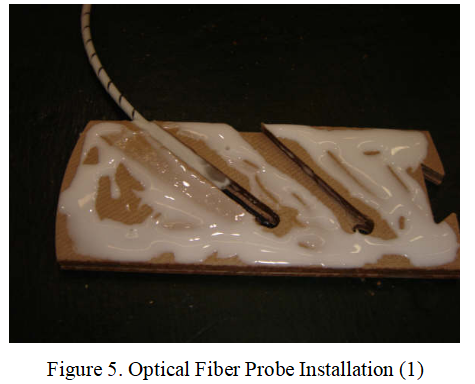

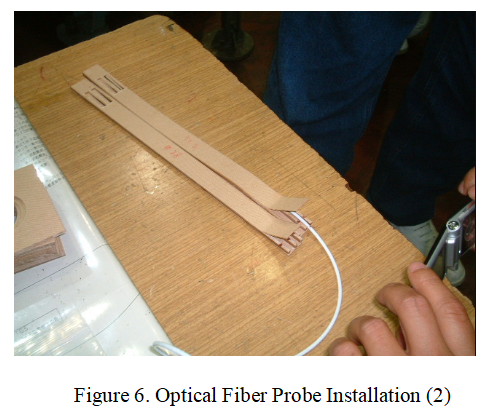

9. Installation of Optical Fiber Temperature Monitor (1) Optical Fiber Probe Installation

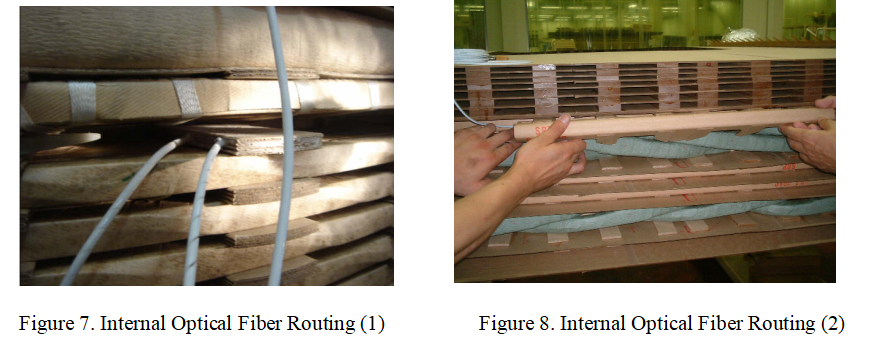

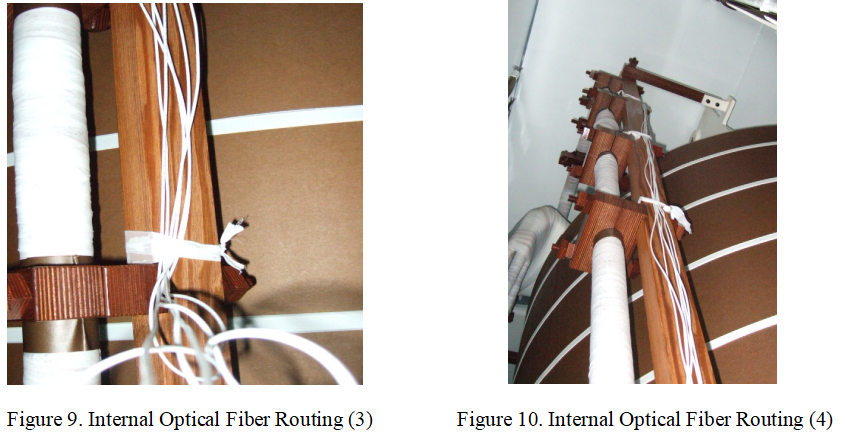

(2) Internal Optical Fiber Routing

(3) Adapter Plate and Flange Mounting

|

CONTACT US

CONTACT US MESSAGE

MESSAGE