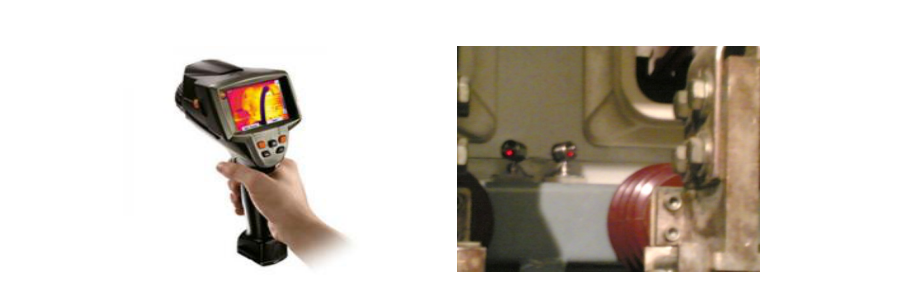

Solution of Fluorescent Optical Fiber Online Temperature Monitoring for SwitchgearSolution of Fluorescent Optical Fiber Online Temperature Monitoring for Switchgear1. Overview Switchgear is the key equipment of power generation, transmission and transformation system. Their safety, reliability and service life are very important to the safe and reliable operation and service life of the whole transmission and transformation system. Most of these high-voltage equipment are enclosed structure. They work in the environment of high voltage, high current and strong magnetic field for a long time. Some joints are heated due to aging or excessive contact resistance, which results in heat accumulation. Heating temperature rise increases the loss of power transmission system. If the heat dissipation is not good, it will endanger the normal operation of equipment, even cause faults. The adverse social impact and economic losses are immeasurable. Many physical and chemical changes (such as partial discharge and partial overheating) inside the switchgear will cause the temperature parameters of the switchgear to change, which makes the temperature rise track of the switchgear different from the normal operation. Temperature plays a decisive role in the aging of insulating materials, so it is particularly important to accurately measure the temperature of switchgear. With the continuous improvement of the automation level of safe power consumption and distribution network, besides monitoring the electrical parameters, direct monitoring of the hot spot temperature of high voltage electrical equipment such as transformer/switchgear/large motor can improve the safe operation of equipment, prolong the insulation life of equipment, instantly judge the actual load capacity of equipment, and maximize the transmission and transformation potential of switchgear to improve the installation. The economic benefits of preparation are of great significance. 2. Comparison of Several Main Temperature Measurement Methods of Switchgear at Present 2.1 Infrared Temperature Measurement Infrared thermometer is suitable for manual inspection and temperature measurement. Due to its flexible use, it has become an important means of temperature detection for high-voltage power equipment. The disadvantage of infrared thermometer is its large volume, high cost, general precision (related to distance), especially its inability to realize on-line real-time monitoring. In addition, infrared ray cannot diffract through the shield and accurately measure the temperature of key contacts, which limits its application in some occasions. Infrared temperature measurement is a non-contact temperature measurement, which is vulnerable to the interference of the environment and the surrounding electromagnetic field. In addition, the space in the switchgear cabinet is very narrow, so it is impossible to install the infrared temperature measurement probe (because the probe must keep a certain safe distance from the object under test and need to be directly on the surface of the object under test), and its temperature measurement accuracy is vulnerable to environmental impact, such as light intensity and fog, will have a certain impact on its measurement accuracy, so its scope of use is greatly restricted.

Infrared Thermography Temperature Measurement System 2.2 Wireless Temperature Measurement The existing wireless temperature measurement scheme uses batteries or CT to supply power to the temperature measurement chip, and then transmits the signal from the temperature measurement chip through wireless chip. Although this scheme realizes the wireless transmission of temperature signal, it needs battery power supply or CT power supply because it belongs to active scheme. Battery power supply needs regular replacement of batteries, and the poor high temperature resistance of batteries in summer has an impact on the operation of the power sector. CT energy acquisition exists if the current of the joint is small, the power cannot be taken out, then the sensor head stops working, and if the current of the joint is large, it is easy to burn CT until the sensor is burned. Using CT energy, the size of the sensor head is large and the location of the sensor head has a great influence on the efficiency of energy acquisition, which lacks universal adaptability. It is necessary to control the magnetic saturation curve for optimum parameters for CT fabrication. If the parameters are not selected properly, the circuit of the sensor will be damaged and the reliability will be affected.

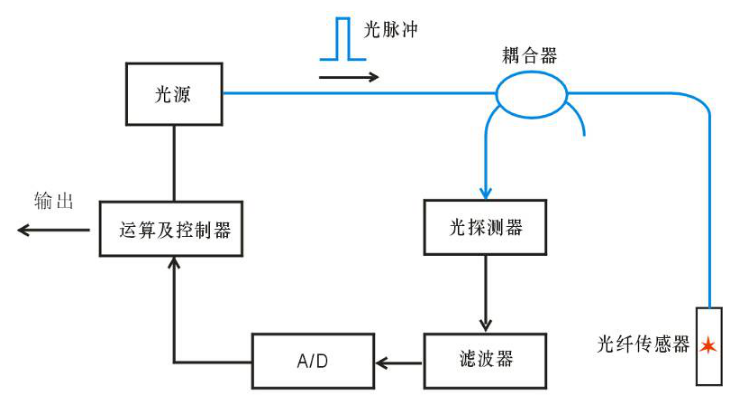

Wireless Temperature Measurement System 2.3 Optical Fiber Temperature Measurement With the development of optical fiber technology, the research of high voltage measurement at home and abroad has used optical fiber technology to measure the electric parameters of power system on-line. Optical fiber transmission system is especially suitable for high voltage measurement because of its high insulation strength, strong anti-electromagnetic interference ability, corrosion resistance, small size and simple structure. Optical fiber thermometer transmits signal by optical fiber. Its temperature sensor head is installed on the surface of charged object, and the thermometer is connected with temperature sensor by optical fiber. Optical fiber temperature measurement can be divided into distributed optical fiber temperature measurement, optical fiber grating, fluorescent optical fiber temperature measurement and other methods. Among them, fluorescent optical fiber temperature measurement has the most obvious advantages, such as long life, no need to calibrate, small probe size and easy installation. The application of fluorescent optical fiber temperature measurement equipment in the United States has been more than 20 years, and many of them are used in such highly demanding environment as 500 KV transformer winding. Facts have proved that the products are safe and reliable.

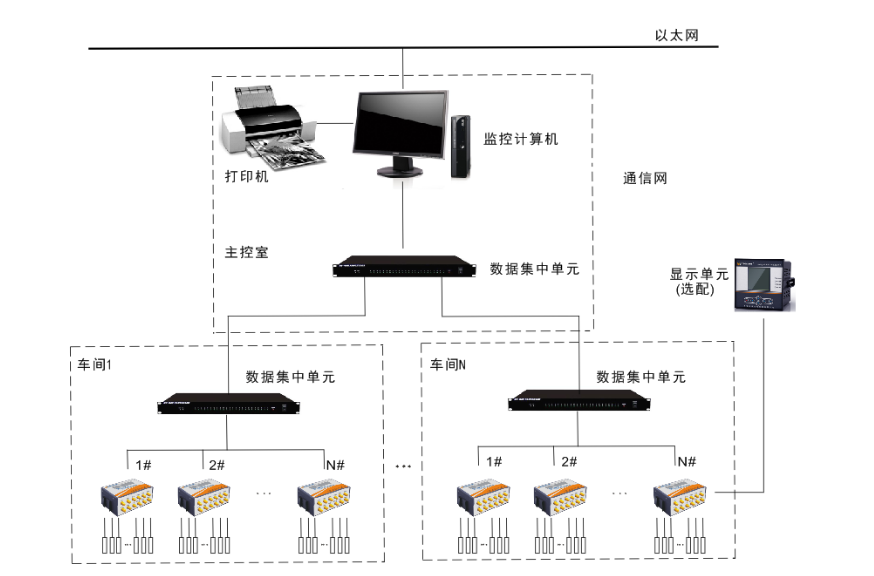

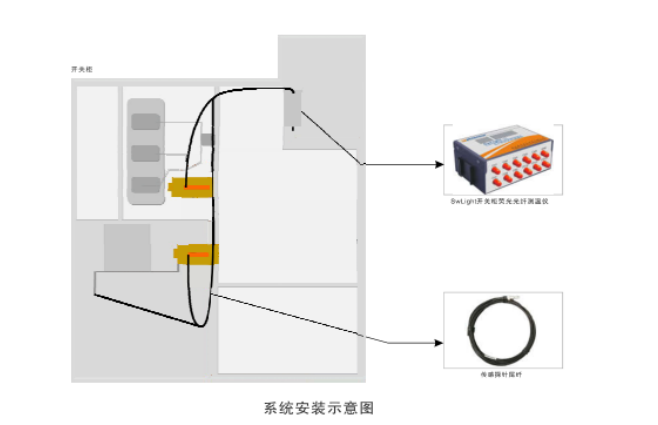

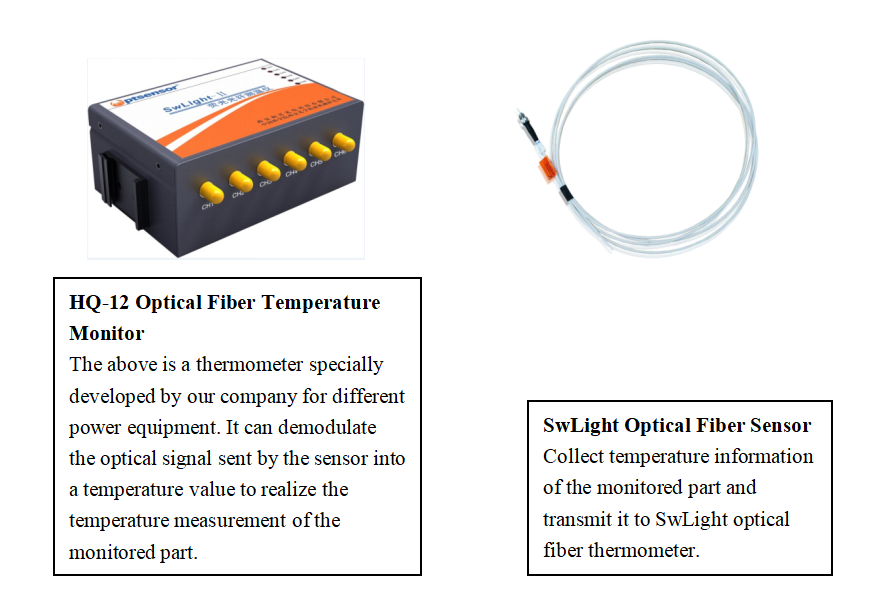

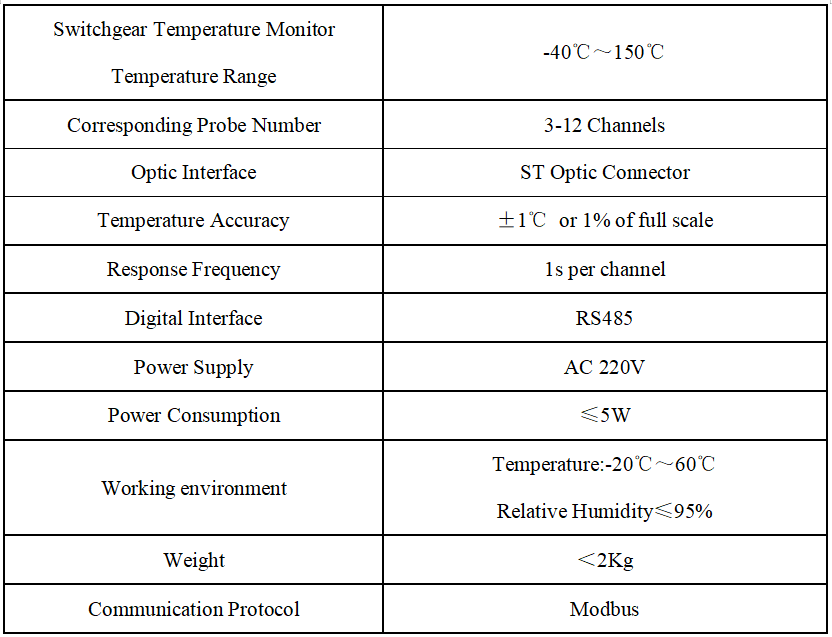

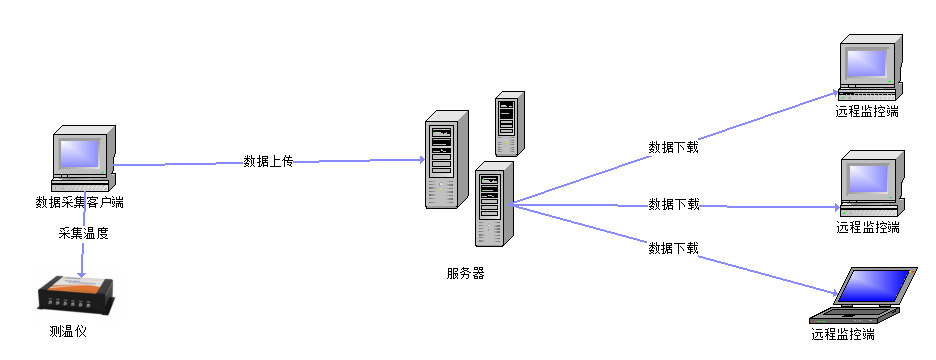

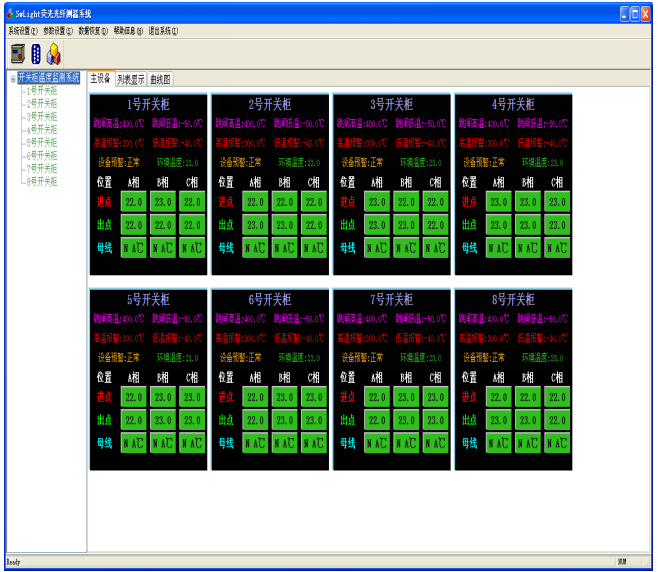

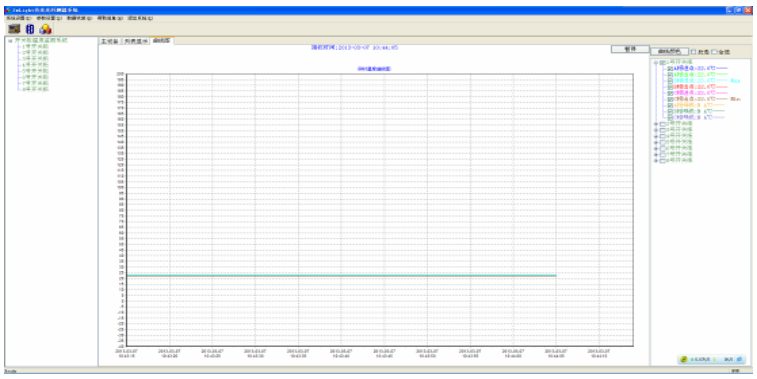

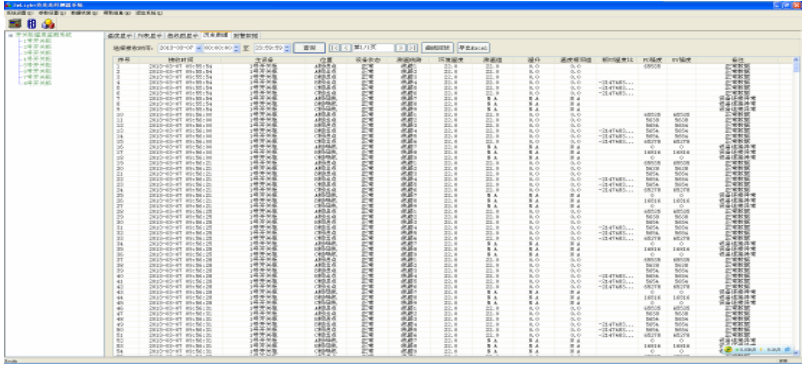

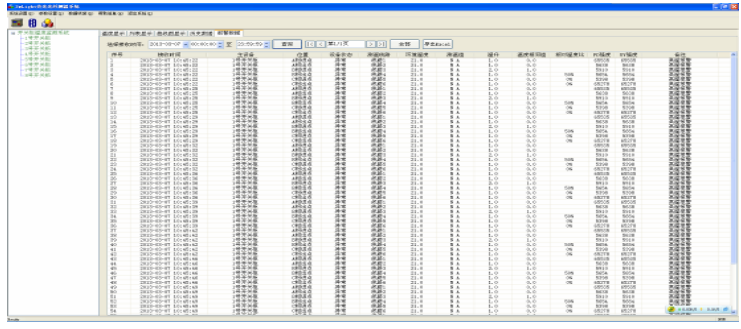

Fluorescent Based Optical Fiber Temperature Monitor for Switchgear 3. Herch’s On-Line Fluorescent Optical Fiber Monitoring System The fluorescent optical fiber on-line monitoring system is a temperature monitoring system designed by Herch for the early prediction of faults and fires caused by insulation ageing or poor contact of high voltage power equipment such as switchgear, cable connectors and transformers in substations. Due to the optical fiber has the characteristic of electrical insulation, intrinsic safety and immunity from electromagnetic interference. The probe of the sensor can be directly installed at the measured point, and the real-time temperature of the measured point can be monitored to predict possible faults and prevent the occurrence of electrical fires. This system is composed of HQ-12 switchgear "hot spot" fluorescent optical fiber temperature measurement system, data centralization unit, upper monitor computer and human-computer interaction software. |

This optical fiber uses LumaProbe SP series optical fiber sensors for matching, the probe size is very small, can be directly installed at the measured point, temperature measurement is accurate, fast response; its tail fiber uses soft, strong special optical fiber, it has the advantages of high transmission bandwidth, signal stability, electromagnetic interference resistance, flexure resistance, high impact strength and fast connection.

This optical fiber uses LumaProbe SP series optical fiber sensors for matching, the probe size is very small, can be directly installed at the measured point, temperature measurement is accurate, fast response; its tail fiber uses soft, strong special optical fiber, it has the advantages of high transmission bandwidth, signal stability, electromagnetic interference resistance, flexure resistance, high impact strength and fast connection.

CONTACT US

CONTACT US MESSAGE

MESSAGE